Profiles

Machined from the highest grade timber, Frontier Pipe Covers are a manufacturing marvel. Laser cut to provide a virtually invisible join.

Frontier PIPE COVERS

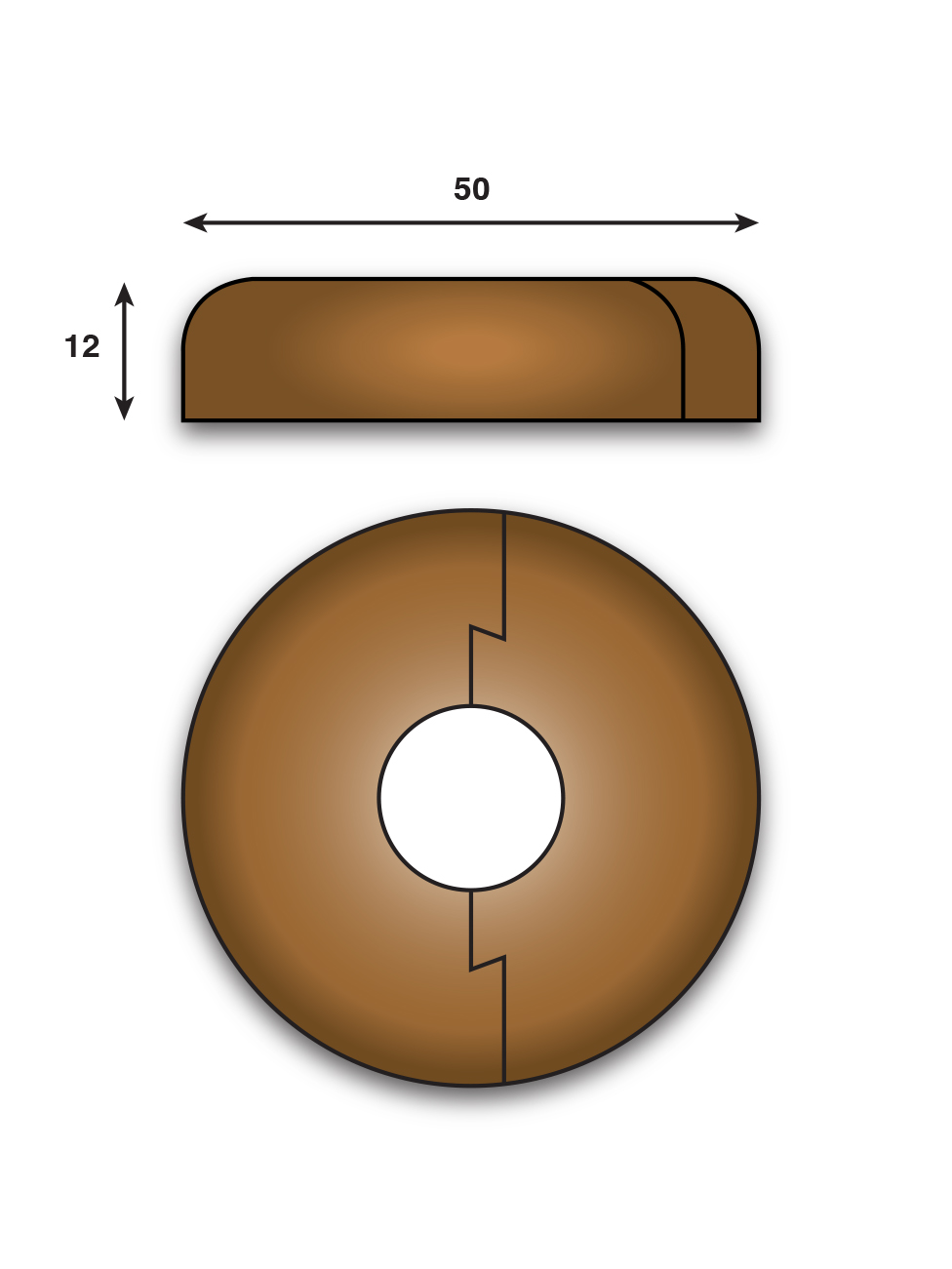

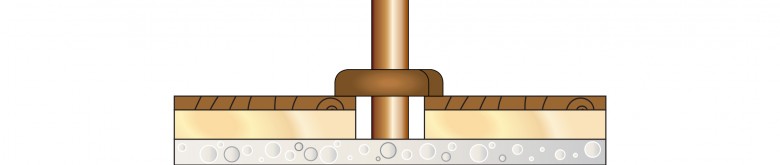

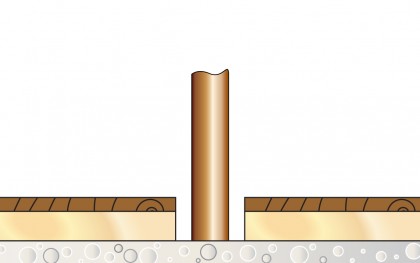

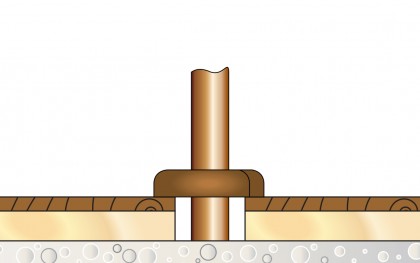

Frontier Pipe Covers are an extra detail that may even go unnoticed on your floor. However, the fact that they are unobtrusive is part of the excellence they provide in the finish. Manufactured to be ultra low profile (standing just 12mm off the floor) and laser cut to provide a virtually invisible join, they effortlessly blend into the floor. The laser cutting provides a ‘jigsaw’ line which enables the two pieces of the pipe cover to be slid apart on the vertical axis.

Only from Parallel do you get the degree of thought and care in a product which is so small and bearly noticed. Pipe Covers are a prime example of our company design and manufacturing ethos to provide the best in everything that we do.

Uses & Application

Laser cut precision, everytime. Perfect for disguising unsighlty areas around pipes quickly and elegantly. Ultra low profile and rounded edges to avoid catching the eye.

Profiles ~ Examples of Usage In situ

Profiles ~ Examples of Usage In situ

What can profiles do for your floor?

Enhance the whole look and feel of your floor. Profiles are often the last thought on the mind of the person who sells or lays the floor but without due care and consideration for what is needed, the floor can look poorly finished. Even without the importance of the aesthetic aspect, profiles play an important roll in the fitting and longevity of the floor, in-particular, solid and engineered wood floors. Profiles provide cover for necessary expansion gaps both around the perimeter of rooms and across door thresholds. Without the necessary expansion, hardwood flooring will bow, dish or push bricks out of walls.

With the correctly specified profiles, perimeter expansion and door threshold covers vanish to become part of the floor.

Floor Preperation

For a flawless finish, preparation is the key. Luckily with Parallel profiles, preparation is kept to the bare minimum. Simply ensure that the substrate floor is clean and relatively level.Not quite what you need?

Haven’t found quite what you are looking for? No problem, just give us a call. Parallel are able to machine bespoke profiles to whatever specification you require.Fixing

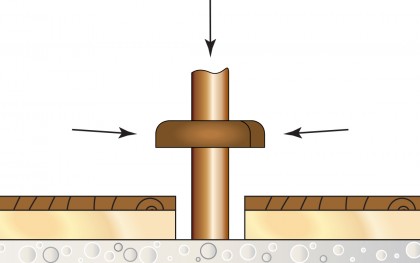

Parallel’s unique fixing system makes installation a breeze. Simply fix the base section to the substrate floor with either an adhesive or screws and then tap the top profile into place with a rubber mallet. The profile will self level in the height adjustable base system giving the perfect finish.Complementary Extras

In addition to profiles to cover gaps between different flooring types or through doorways, Parallel also manufactures skirting, architrave, scotia, quadrant, stairnosing, pipe covers/collars and more from the same high quality hardwoods. This enables continuity throughout the room or building.Innovation

Leading the way with an uncompromising attitude to product design and customer service, what is run of the mill to us is impossible to others.

Laser Cut Profiles

Laser Cut Profiles

Beautiful Design

Beautiful Design

Laser Cut Profiles

It may sound a little like science fiction but the reality is that laser cutting of small timber objects is a hassle free and highly reliable way of manufacturing. Lasers work by focussing an intense beam of light in a very tight path, allowing for very delicate and complex designs and patterns to be created. Before the introduction of laser cut pipe covers it was necessary to cut pieces by saw which always removes a relatively large portion of the timber. This makes joining the two pieces back together difficult. Added to which, often dowls were needed to hold the two pieces together. This led to a highly inaccurate product and consequently issues with continuity and quality.

Frontier Pipe Covers really are best seen to be believed.

colour matching

Send us your board and we will provide profiles to match it! Using our comprehensive colour database, there are very few finishes we are unable complement.

staining process

Starting with an unfinished base timber, various stains, waxes, oils and enhancers are hand applied to ensure an even and consistent colour. Once dry, the top coat is applied to give the desired finish, whether that be matt oil or gloss lacquer or anything else in between.

Fitting

Minimal preparation, beautiful finish. Fix & forget, walk away without worry of having to return to replace or repair Parallel products.

Fitting Method

Tools for the job;

- A Pair of Hands!

Frontier Woodline Pipe Covers couldn’t be easier to fit. The laser cut jigsaw system simply slides together around the pipe to cover unsightly holes where radiator pipes are required to go through wood and laminate floors.

1, Carefully slide apart the two pieces of the pipe cover. Look closely and you will see the feint line where the two pieces join.

2, Place one half of the pipe cover around the pipe and place on the floor.

3, From above, hold the half in situ steady whilst sliding the other half into place to complete the ring. No glue is necessary meaning they can be removed and replaced as required.

Prepare

Prepare

Fix

Fix

Forget

Forget