Profiles

Frontier Coverplate is simply designed to work. The pinnacle of substance over style. Quickly cover large or small gaps between floors of different types.

Frontier COVERPLATE

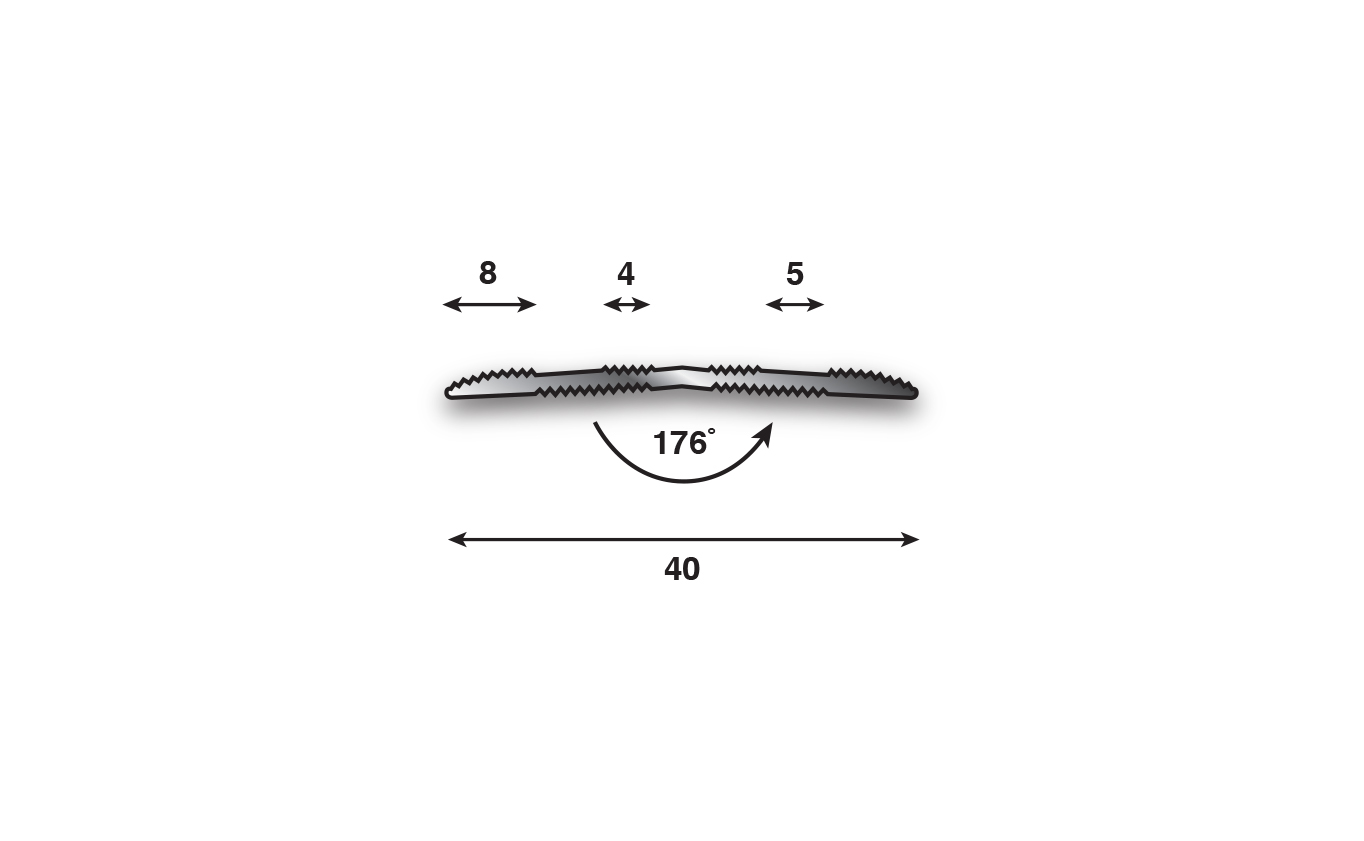

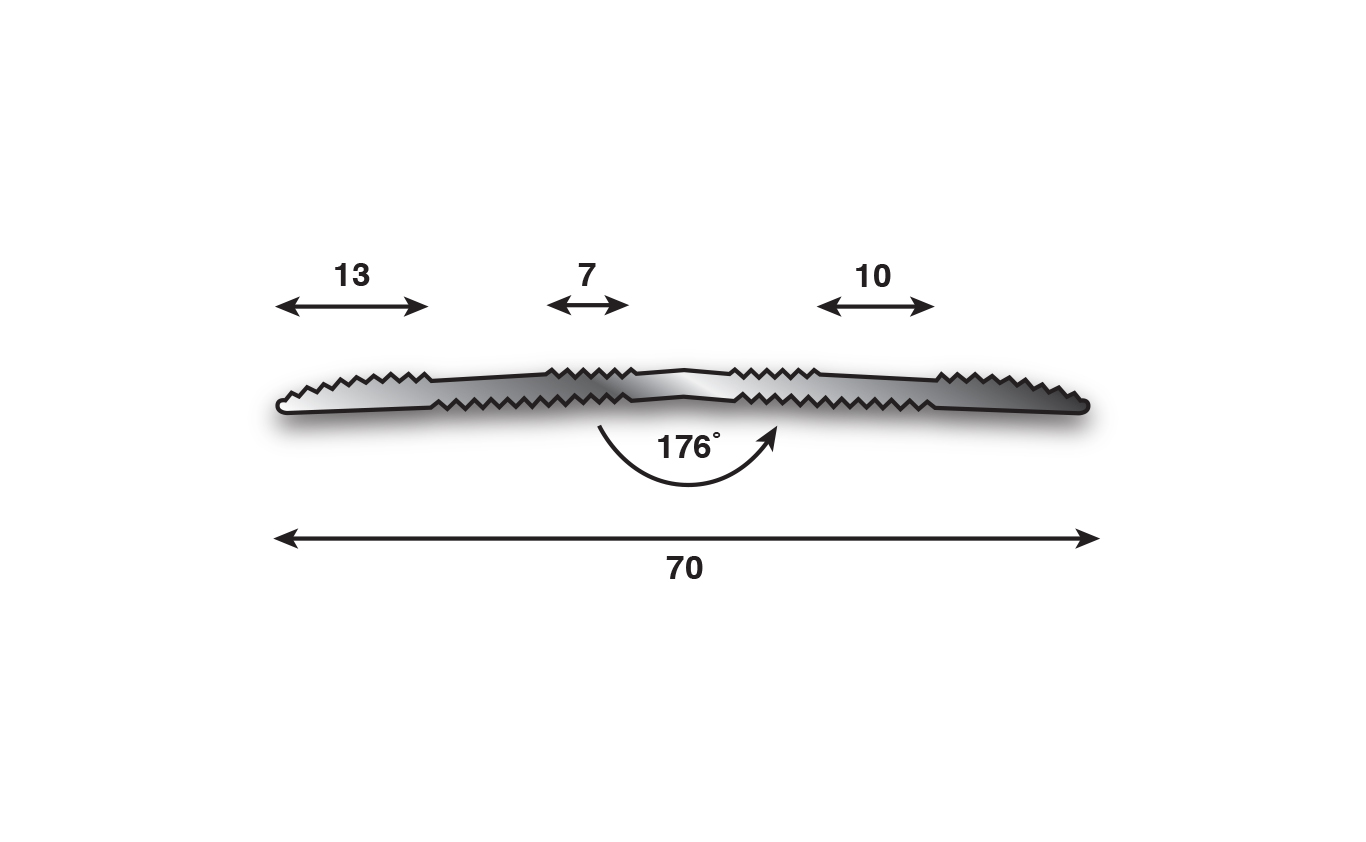

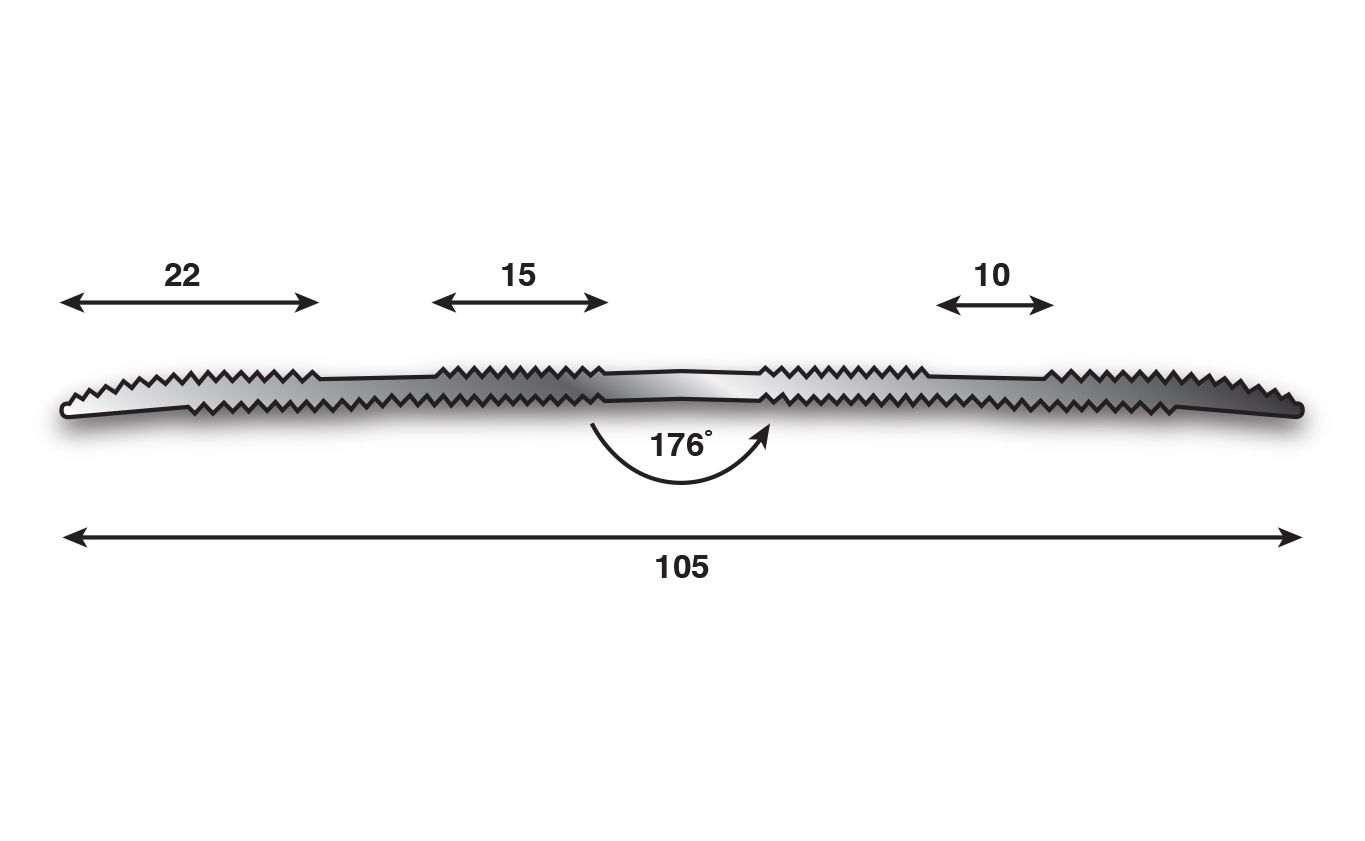

Frontier Coverplate comprises a range of sections that are principally designed for use in the contract sector, more specifically, in leisure contracts. Three different widths, flexible lengths and multiple drilling options allow for use in many applications and rapid fitting. Coverplate is milled from top grade Aluminium, producing a quality section which is both reliable and aesthetically pleasing.

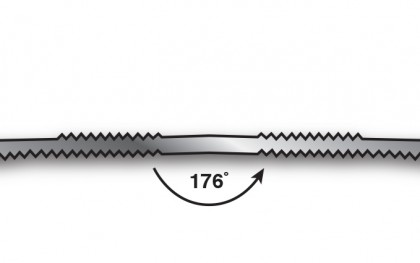

Coverplate sections are ‘cranked’ by a few degrees under 180. This allows the profiles to be used even when floors don’t meet at the same level. Another small example of Parallel’s uncomprimising attitude to design and engineering.

Uses & Application

The perfect solution for covering large gaps, expansion or otherwise, between floors. Particularly useful in contract applications. Hardwearing and durable.

Profiles ~ Examples of Usage In situ

Profiles ~ Examples of Usage In situ

What can profiles do for your floor?

Enhance the whole look and feel of your floor. Profiles are often the last thought on the mind of the person who sells or lays the floor but without due care and consideration for what is needed, the floor can look poorly finished. Even without the importance of the aesthetic aspect, profiles play an important roll in the fitting and longevity of the floor, in-particular, solid and engineered wood floors. Profiles provide cover for necessary expansion gaps both around the perimeter of rooms and across door thresholds. Without the necessary expansion, hardwood flooring will bow, dish or push bricks out of walls.

With the correctly specified profiles, perimeter expansion and door threshold covers vanish to become part of the floor.

Floor Preperation

For a flawless finish, preparation is the key. Luckily with Parallel profiles, preparation is kept to the bare minimum. Simply ensure that the substrate floor is clean and relatively level.Not quite what you need?

Haven’t found quite what you are looking for? No problem, just give us a call. Parallel are able to machine bespoke profiles to whatever specification you require.Fixing

Parallel’s unique fixing system makes installation a breeze. Simply fix the base section to the substrate floor with either an adhesive or screws and then tap the top profile into place with a rubber mallet. The profile will self level in the height adjustable base system giving the perfect finish.Complementary Extras

In addition to profiles to cover gaps between different flooring types or through doorways, Parallel also manufactures skirting, architrave, scotia, quadrant, stairnosing, pipe covers/collars and more from the same high quality hardwoods. This enables continuity throughout the room or building.Innovation

Leading the way with an uncompromising attitude to product design and customer service, what is run of the mill to us is impossible to others.

Off Set, Centred & Staggered Drilling Options

Off Set, Centred & Staggered Drilling Options

Cranked Profile

Cranked Profile

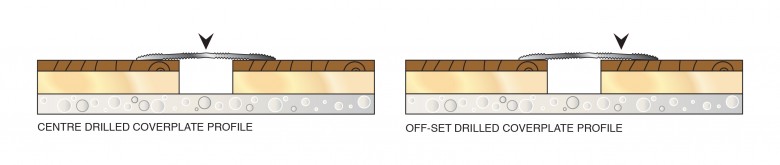

flexible drilling options

Centre drilled? Off-set? Staggered? No matter what is needed, Coverplate can be provided correctly drilled to suit. Often drilling options are a major consideration of the fixing. Choosing the correct one makes the whole job much more straight forward. Centre drilled sections are ideal for fixing the profile directly through to the substrate floor below. This allows for the floors to move on both sides. Off-set drilled sections work best when there is a permanent non moving floor on one side and a moveable floor on the other. This allows the profile to be fixed to the permanent flooring, leaving the the other floor free to expand and/or contract as it pleases. The Staggered drilling option is preferred where extra security in the fit is required. The profile is screw fixed on both sides in a staggered pattern, this method provides an extremely strong bond.

bespoke options

We know that not all jobs are standard. If required, we can cut to specialised lengths and provide bespoke drilling options for both pattern and spacing.

ral powder coating

On those special occasions where even our standard colours aren’t what are required, we can offer powder coating of our Aluminium profiles. Achieved by electrically charging the materials to encourage the colour to ‘stick’, powder coating offers a full spectrum of standardised colours to pick from.

Fitting

Minimal preparation, beautiful finish. Fix & forget, walk away without worry of having to return to replace or repair Parallel products.

Fitting Method

Tools for the job;

- Hand Saw

- Drill

- Screw Driver

- High-Grab Adhesive

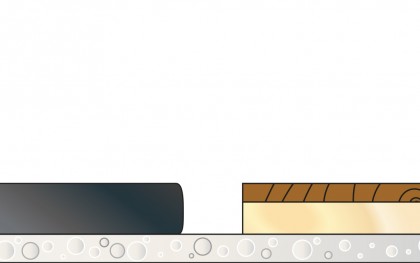

The Frontier Coverplate profiles are quick and simple to fit, whether you are a seasoned carpenter or a DIY beginner. Follow the steps below, ensuring that you start with a clean and clear environment and the correct profile has been selected;

1, Trim down the profile and base to the desired length (if neccessary). Be sure to double check measurements before cutting! The profile may also need notching out in the corners to get a neat fit with the door frame.

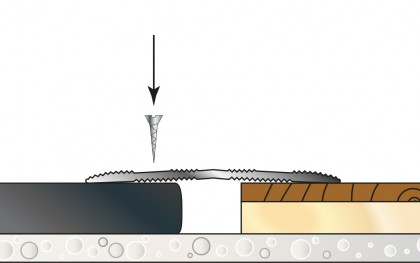

2, Screw and/or glue the profile, either through the central gap between the floors or offset fix it to the flooring which doesn’t require expansion or movement. If both flooring types are ‘wood’ then fix only to one side to allow movement under the Coverplate section.

Prepare

Prepare

Fix

Fix

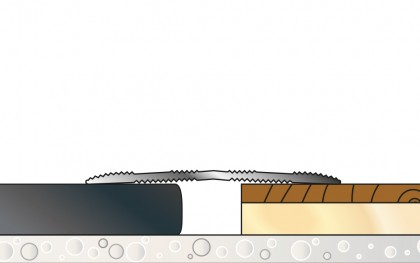

Forget

Forget